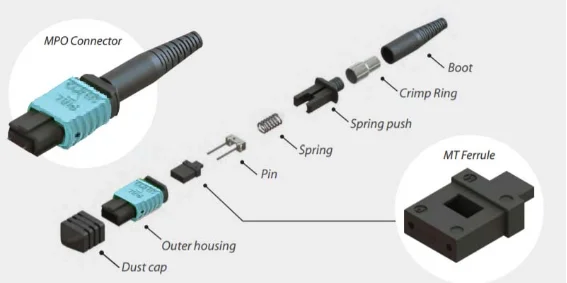

What is MPO/MT Ferrule and where it can be used?

MPO/MT Ferrule is a compact design, high-density, and small volume multi-core plastic plug, whose main function is to achieve precise physical docking of optical fibers. MT plug is a square plug made of PPS plastic injection molding, which has excellent characteristics such as good thermal stability, high mechanical strength, high temperature resistance, corrosion resistance, flame retardancy, and good dimensional stability. It can achieve high-density and high-precision connection of multiple optical fibers, and each fiber has low loss performance. It is widely used in the manufacturing of MPO fiber connectors and optocoupling of devices.

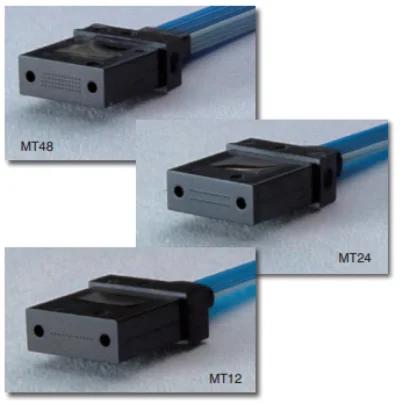

MPO/MT Ferrule Types

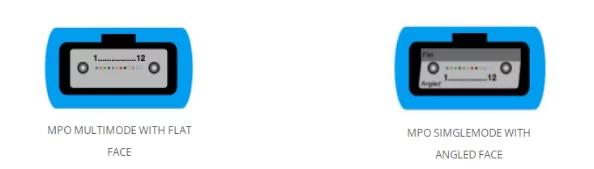

All multimode MPOs have a flat front face while all single-mode have an angled front with flat surface towards the keyway.

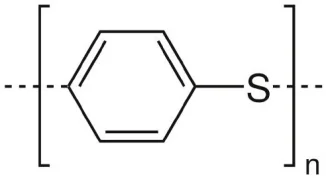

Material Selection of Ferrule

MT Ferrule, made from high quality special mineral filled PolyPhenylene Sulfide (PPS). High quality special mineral filled PPS is ideal for precise tolerance molded components because it hasminimal water absorption and has a very low coefficient of linear thermal expansion. As such, the ferrule offers excellent performance and properties for all environments.

Who is the professional manufacturer of this special PPS?

Guangdong Suqing Industrial Co., Ltd.focuses on customized production of high performance engineering plastics.Our SUZHOU factory in Jiangsu Province is specialised in this high quality special mineral filled PolyPhenylene Sulfide (PPS). We can also offer most type of plastics with the function of Thermal conductive,Electrically conductive,antistatic Anti-friction,Anti-Scratch,Anti-hydrolysis,Anti-corrosion Chemical resistance,Super high tempreture, Super Low tempreture High toughness,High impact, High Modulus,High flame retardant etc.PPA PPS PA46 POM PET PPO PEEK PA66 are the key product lines.It may be your best choice to customize the material for your plastic parts or cost down replace your current grades with equal quality.

How is the product quality of the SUQING PPS for MPO/MT Ferrule?

SUQING SQ286 STCE is a 70% special mineral reinforced modified polyphenylene sulfide with a stable coefficient of thermal expansion. Especially suitable for pursuing ultra-high dimensional stability and ultra-high precision in environments such as light, heat, and electricity, it can be widely used in communication, military, semiconductor, and other fields. This product also has the advantages of corrosion resistance, hydrolysis resistance, high temperature resistance, low water absorption, and good insulation of ordinary glass fiber modified PPS.

Comprehensive performance comparison between SUQING SQ286 STCE and MT/MPO Ferrule Grade of Japan P COMPANY

| TEST ITEM | UNIT | Japan P COMPANY PPS | SUQING SQ286 STCE | TEST STANDARD |

| Density | g/cm3 | 1.85 | 1.84 | ISO 1183 |

| MFR (300℃,5Kgf) | g/10min | 28.7 | 29.3 | ISO 1133 |

| Water absorption rate(23℃,aquatic 24h) | % | 0.01 | – | ISO 62 |

| HDT(1.8MPa) | ℃ | 185 | – | ISO 75 |

| Tensile strength | Mpa | 52.6 | 68.8 | ISO 527 |

| Tensile modulus | MPa | 10979 | 11723 | ISO 527 |

| Elongation break | % | 1.11 | 1.29 | ISO 527 |

| Flexural strength | MPa | 98.57 | 103 | ISO 178 |

| Flexural modulus | MPa | 11990 | 13060 | ISO 178 |

| Izod notched impact strength | kJ/m2 | 3.16 | 3.04 | ISO 180 |

| Linear coefficient of thermal expansion,MD | 10-5/℃ | 2 | – | ISO 11359 |

| Linear coefficient of thermal expansion,TD | 10-5/℃ | 2 | – | ISO 11359 |

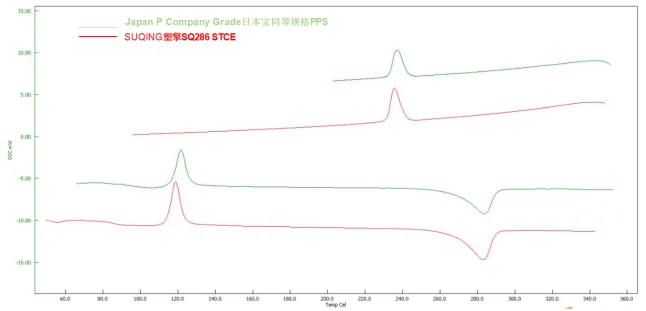

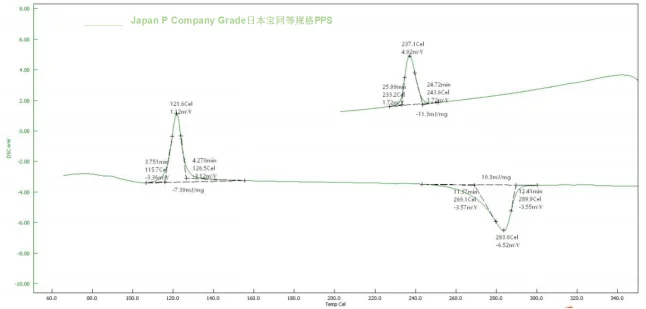

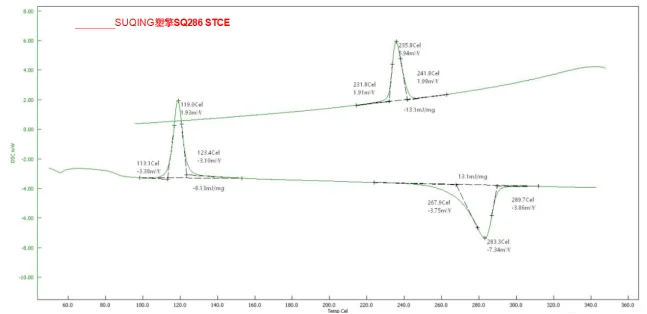

Differential scanning calorimetry,DSC test

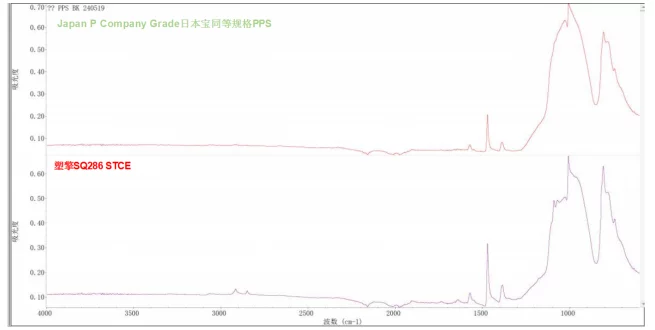

Comparison results of infrared spectra between SUQING SQ286 STCE and MT/MPO Ferrule Grade of Japan P COMPANY

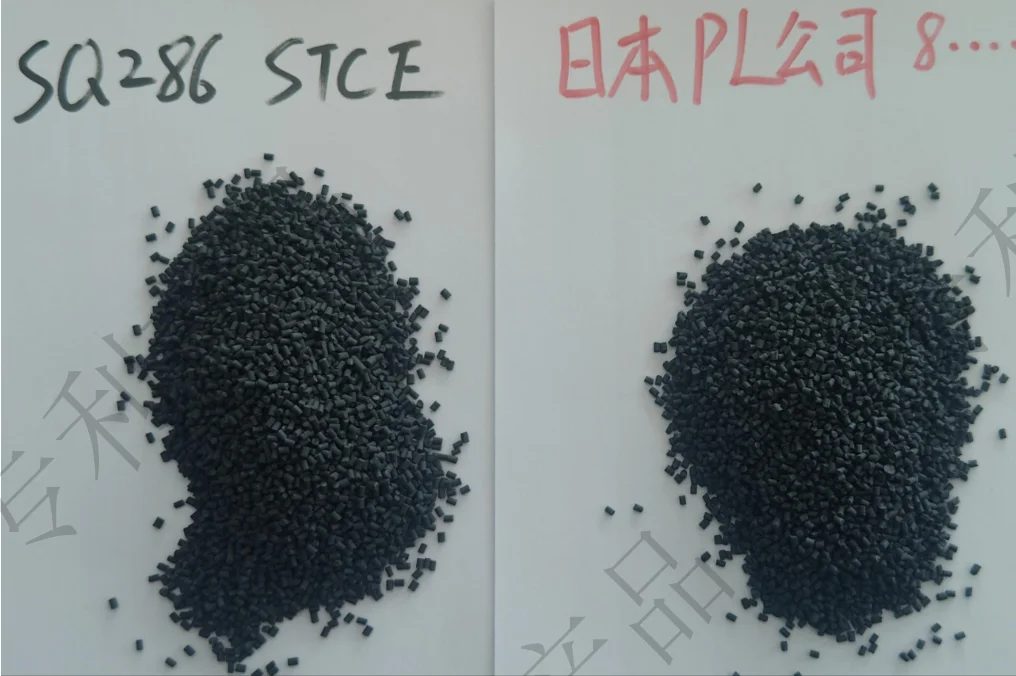

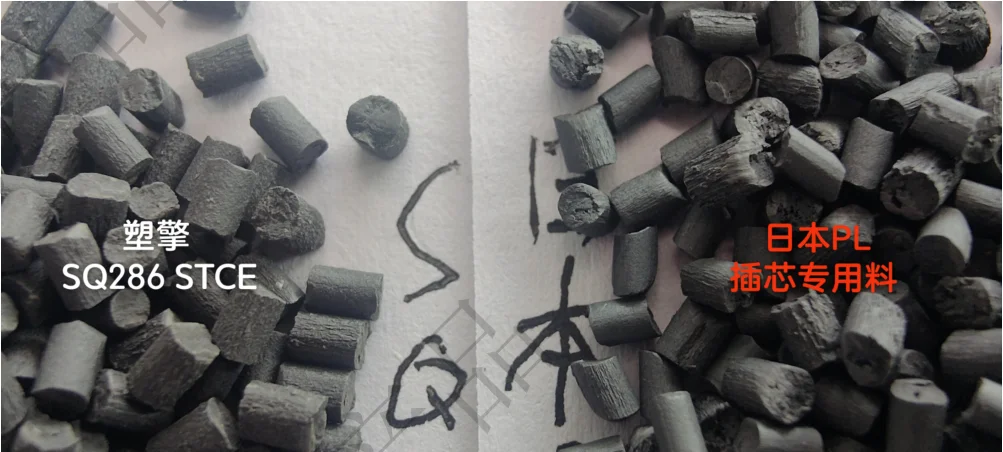

Pellets Appearance comparison between Suqing SQ286 STCE and Japan Pcompany

Advantages of SUQING PPS SQ286 STCE for MT/MPO Ferrule

After a comprehensive comparison of mechanics and thermodynamics, we found that the SQ286 STCE can completely replace the equivalent grade produced by Japan P COMPANY.

Click here for more infomation about SQ286 STCE

Contact MT/MPO Ferrule PPS Polymer Expert

Michael Sher

+86 13926159974

mlc@soliao.com